Rev Up Your Business with Quality Diesel Engine Parts

The durability and efficiency of any vehicle largely depend on the quality of its engine components. Diesel engines, in particular, are renowned for their robustness and long service life. However, to maintain that longevity, it is crucial to use high-quality diesel engine parts. In this article, we'll dive deep into the world of diesel engine parts, the role of reliable spare parts suppliers, and how these components can significantly enhance business operations.

The Importance of Diesel Engine Parts

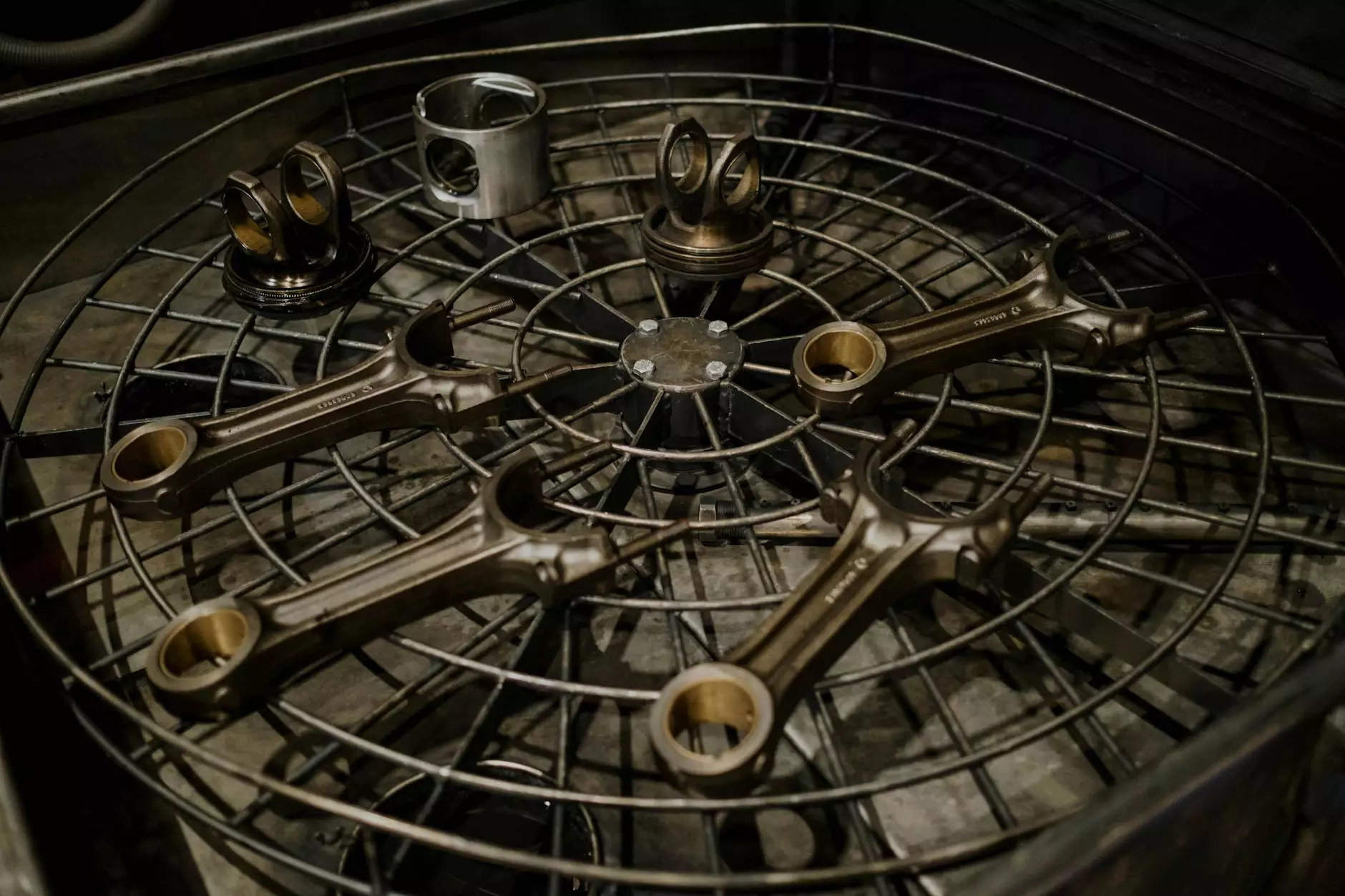

Understanding diesel engine components is essential for anyone involved in the automotive industry, especially businesses that rely on diesel-powered machinery. Each part plays a pivotal role in ensuring seamless operation. Let's explore some of the core components and their significance:

- Cylinder Block: The cylinder block is the heart of the engine where fuel combustion takes place. It's crucial to choose a well-manufactured cylinder block to uphold engine performance.

- Injectors: Diesel injectors are responsible for spraying fuel directly into the combustion chamber. They need to be precise and reliable.

- Pistons: These cylindrical components convert fuel energy into mechanical energy. High-quality pistons ensure efficient work cycles and reduce wear and tear.

- Crankshafts: Crankshafts convert linear motion from the pistons into rotational motion, allowing the engine to do its work effectively.

- Gaskets: Engine gaskets create a seal between different engine parts, preventing leaks and maintaining pressure.

Choosing the Right Spare Parts Suppliers

When it comes to sourcing engine parts, not all suppliers are created equal. Choosing the right supplier can make a significant difference in your operational efficiency and overall success. Here are key factors to consider when selecting spare parts suppliers:

1. Quality of Products

The quality of engine parts directly impacts the performance and reliability of your machines. Always opt for suppliers who offer product certifications and adhere to industry standards. Working with reputable brands ensures you're getting authentic and durable parts.

2. Range of Products

It’s vital that your supplier offers a broad range of products. Whether you are looking for cylinder blocks, injectors, or gaskets, having a single supplier who can meet all your needs saves time and reduces operational hassle. Look for suppliers who provide comprehensive online catalogs, like client-diesel.com.

3. Customer Support

Strong customer support is an indicator of a reliable supplier. They should be able to assist you in quickly resolving any issues related to product quality or delivery. Check reviews and testimonials to gauge their support efficacy.

4. Competitive Pricing

While quality should be prioritized, competitive pricing also matters. Suppliers should offer products that match your desired budget without compromising quality. Bulk discounts or loyalty programs can also be beneficial to increase your bottom line.

Benefits of Using Quality Diesel Engine Parts

Investing in quality diesel engine parts comes with numerous advantages, making it a smart choice for any business. Here are some key benefits:

1. Enhanced Performance

Quality engine parts ensure that your vehicles and machinery operate at peak efficiency. This boost translates into better fuel economy and overall effectiveness on the job site.

2. Reduced Downtime

When you utilize reliable parts, the chances of unexpected breakdowns significantly decrease. This translates to increased uptime for your business, allowing you to meet deadlines and maintain customer satisfaction.

3. Longer Lifespan

High-quality diesel engine parts can extend the lifespan of your engines. This longevity means lower long-term costs, as you won’t have to replace parts as frequently.

4. Improved Safety

Safety is paramount in any industrial operation. Using certified parts ensures that your machinery operates safely, reducing the risk of accidents caused by mechanical failures.

Real-World Applications of Quality Diesel Engine Parts

The versatility of diesel engine parts allows them to be used across various sectors. Here are some common applications:

- Construction: Equipment such as bulldozers and excavators rely on robust diesel engines to perform strenuous tasks.

- Agriculture: Tractors and harvesters powered by diesel engines are essential for modern farming, increasing productivity.

- Transport: Trucks and cargo vehicles predominantly use diesel engines for their fuel efficiency and durability.

- Marine: Many ships and boats utilize diesel engines for their reliability and power, especially in commercial fishing and transportation.

How to Maintain Diesel Engines for Longevity

Purchasing quality parts is just the start; maintaining diesel engines is crucial for maximizing their performance and lifespan. Here are some best practices:

1. Regular Inspections

Conduct frequent inspections of your equipment to spot any potential issues before they escalate. Look for signs of wear and tear and promptly replace any affected parts.

2. Engine Cleanliness

Keep your engines clean to avoid dirt accumulation that can obstruct critical components. Regular cleaning helps in maintaining optimal performance.

3. Proper Lubrication

Ensure that your engines are adequately lubricated to minimize friction and reduce wear. Use high-quality lubricants and follow the manufacturer’s recommendations.

4. Follow Maintenance Schedule

Stick to the recommended maintenance schedule provided by the engine manufacturer. This schedule includes routine oil changes, filter replacements, and other essential checks.

Invest in Quality for Future Growth

As businesses evolve, the need for reliable machinery only grows. Investing in high-quality diesel engine parts is not just a choice; it is a vital strategy for sustainability and growth. With the pressure of competition and the demand for efficiency, ensuring that your engines are fitted with the best components available is paramount.

Conclusion

Quality diesel engine parts are the backbone of any successful operation dependent on diesel machinery. From selecting the right spare parts suppliers to maintaining your engines, each step in this process is crucial. By prioritizing the procurement of top-notch components, businesses can improve performance, reduce operational costs, and enhance safety—all crucial factors for long-term success. Make informed decisions and invest wisely in your diesel engine systems. Remember, your choice of parts can either fuel your growth or stall your progress.

For more information on reliable diesel engine parts and how they can benefit your business operations, explore this detailed product page.

https://client-diesel.com/en/products/cylinder-block