The Comprehensive Guide to Die Casting Molds in Metal Fabrication

Understanding Die Casting Molds

Die casting molds are essential tools in the metal fabrication industry, used for producing intricate and high-precision components. These molds are designed to withstand the intense pressures and temperatures associated with the injection of molten metal. The die casting process offers a plethora of advantages such as dimensional accuracy, excellent surface finish, and the ability to create complex geometries.

What is Die Casting?

Die casting is a manufacturing process that involves forcing molten metal into a mold cavity under high pressure. This technique is ideal for producing metal parts with high levels of detail and repeatability. Typically, metals such as aluminum, zinc, and magnesium are used in die casting due to their favorable properties.

The Key Benefits of Die Casting

- High Precision: Die casting molds allow for the production of parts that meet tight tolerances and intricate designs.

- Complex Shapes: The process can accommodate complex shapes that would be difficult or impossible to achieve through other manufacturing methods.

- Cost-Efficiency: Once the mold is created, the cost of producing additional parts is significantly reduced.

- Excellent Surface Finish: Parts produced via die casting have a smooth surface finish, often requiring less post-processing.

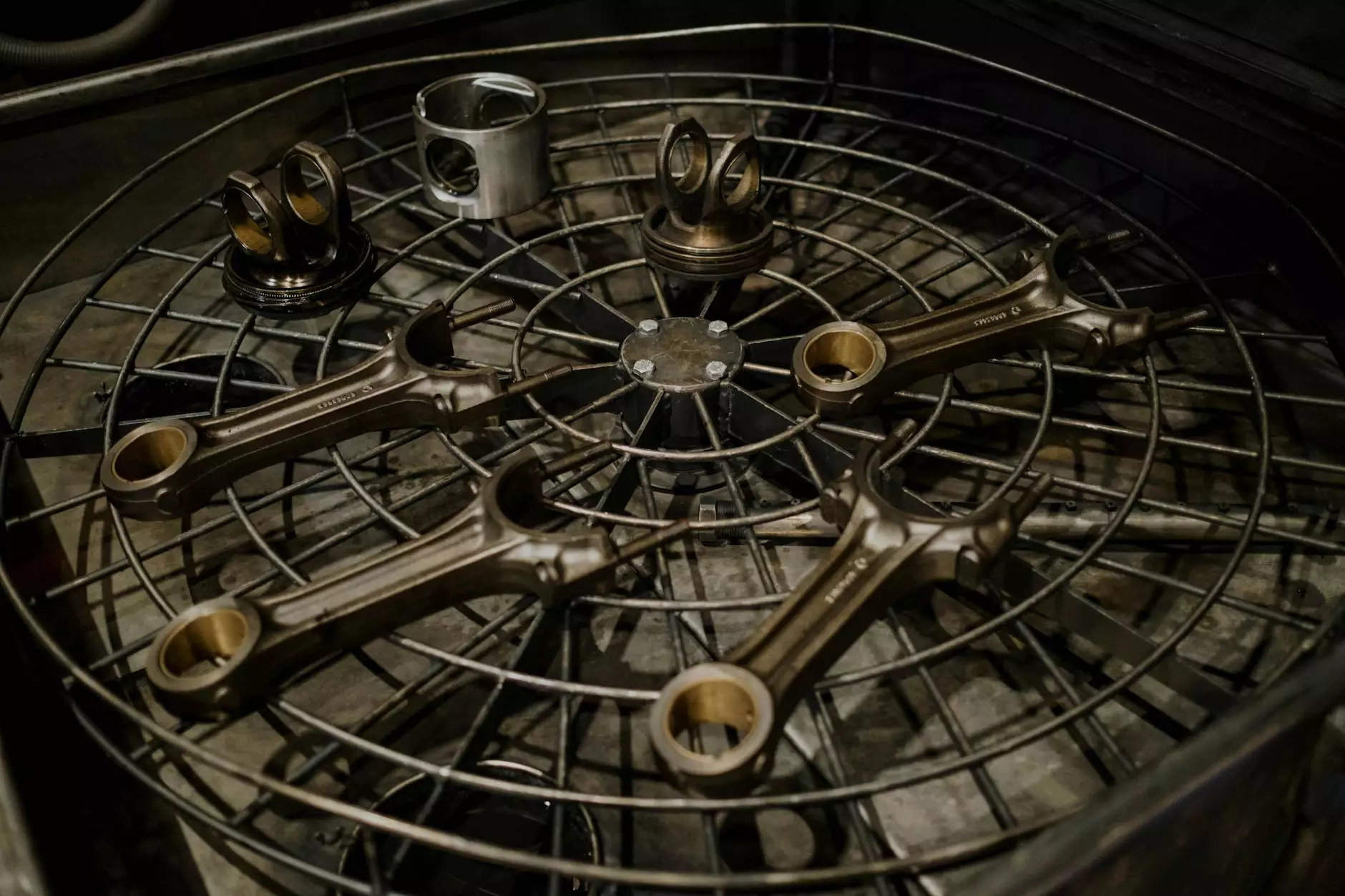

The Components of Die Casting Molds

A typical die casting mold consists of several key components:

- Mold Cavity: The part of the mold that defines the shape of the finished part.

- Gate: The entry point for the molten metal into the mold cavity.

- Vents: Openings that allow air to escape from the mold during filling, preventing pressure buildup.

Types of Die Casting Molds

Die casting molds can be categorized into two main types:

1. Cold Chamber Die Casting Molds

In cold chamber die casting, the molten metal is poured into the chamber before being injected into the mold. This method is commonly used for metals with high melting points, such as aluminum and copper.

2. Hot Chamber Die Casting Molds

Hot chamber die casting involves a chamber that is kept at a high temperature, which allows for continuous feeding of molten metal. This method is typically used for zinc and lead alloys, enabling quicker production cycles.

Applications of Die Casting Molds

Die casting molds are utilized across various industries due to their versatility. Some of the most common applications include:

- Automotive Parts: Engine components, transmission cases, and decorative trims.

- Consumer Electronics: Housings for electronic devices, connectors, and heat sinks.

- Industrial Equipment: Components for machinery, pumps, and valves.

The Importance of Material Selection

Choosing the right material for die casting molds is crucial for achieving optimal performance. High-quality steel is often used due to its durability and ability to withstand repeated heat cycles. A well-chosen material not only extends the life of the mold but also enhances part quality.

Design Considerations for Die Casting Molds

The design of a die casting mold significantly impacts the production process. Factors such as draft angles, wall thickness, and parting lines must be carefully considered to ensure ease of production and the quality of the final product.

1. Draft Angles

Draft angles are critical for the mold's ease of release. A minimum draft angle of 1°-2° is typically recommended to facilitate the removal of the part without causing damage.

2. Wall Thickness

Uniform wall thickness is important for consistent cooling and strength. Thin walls can lead to insufficient structural integrity, while excessively thick walls can cause uneven cooling and defects.

3. Parting Lines

Careful placement of the parting line minimizes the need for machining and enhances the aesthetic quality of the part. The parting line should ideally be placed where it has the least visual impact.

Maintenance and Care of Die Casting Molds

Proper maintenance of die casting molds is essential for ensuring longevity and optimal performance. Here are some best practices:

- Regular Inspections: Frequent checks for wear and tear can help identify potential issues before they lead to significant problems.

- Cleaning: Keep the molds clean from residues that can affect the quality of the cast parts.

- Lubrication: Appropriate lubrication reduces friction, promoting smoother operation and reducing wear.

Future Trends in Die Casting Technology

As industries evolve, so do the technologies associated with die casting molds. The future is set to see advancements in:

1. Automation

Increased automation can enhance efficiency and precision in the die casting process, leading to better quality products and reduced labor costs.

2. 3D Printing

The integration of 3D printing in mold design can speed up prototyping and reduce costs by allowing for rapid adjustments and iterations.

3. Advanced Materials

The development of new alloy compositions and mold materials will likely improve the performance and lifespan of die casting molds.

Conclusion: Embracing the Future with Die Casting Molds

In conclusion, die casting molds play a pivotal role in the modern manufacturing landscape. Their ability to produce high-quality, complex parts efficiently underscores their importance in various sectors such as automotive, electronics, and heavy machinery. By understanding the intricacies of die casting and focusing on factors such as design, maintenance, and technology trends, businesses can leverage the full potential of die casting molds and achieve outstanding results for their metal fabrication needs. Companies like DeepMould.net are at the forefront of this evolving industry, committed to delivering excellence.

Get in Touch

If you're interested in learning more about die casting molds or looking for a reliable partner in metal fabrication, visit DeepMould.net. Our expert team is ready to assist you with your manufacturing needs and ensure your projects exceed expectations.